Assistance technique

CHAUVIN-MÉCAGRAPHIC

Formation, prestations, assistance technique

En tant que vendeur de machines-outils et logiciels C.F.A.O, nous nous devons de vous former à l’utilisation de nos produits ; ainsi la transmission de nos compétences à travers notre expérience est une mission qui nous engage au quotidien auprès de nos clients.

Nous sommes enregistrés en tant qu’organisme de formation professionnelle depuis 2009.

Nous vous proposons les formations suivantes :

Usinage conventionnel

Formation compléte tournage/fraisage incluant :

- Découverte de la machine

- Présentation des différents organes et terminologie

- Caractéristiques techniques requises en fonction des travaux à réaliser

- Choix des outils de coupe

- Principaux matériaux utilisés dans l’industrie métallurgique en fonction des applications

- Réglages de base et mise en service des machines

- Choix des conditions de coupe

- Types d’usinages selon configuration de la pièce

- Métrologie et contrôles

- Maintenance préventive des équipements de production

Usinage CNC

- Initiation à la commande numérique et découverte de la machine CNC

- Syntaxes de la programmation, coordonnées, fonctions préparatoires, cycles fixes

- Définition et établissement d’un programme pièce

- Montage et étalonnage des porte-outils

- Définition des origines pièce et programme

- Chargement et test du programme

- Corrections dynamiques, modifications du programme, optimisation des paramètres

- Métrologie et contrôles

- Maintenance préventive des équipements de production

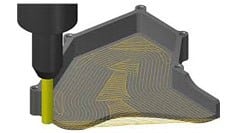

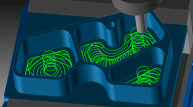

Conception & fabrication assistée par ordinateur

- Découverte de l’interface graphique et présentation du logiciel

- Outils de conception et dessin

- Imports de fichiers et mise en position pour l’usinage

- Fabrication : mise en oeuvre des parcours d’outils

- Optimisation des usinages en utilisant les stratégies

- Utilitaires spécifiques

- Génération du programme pièce et chargement sur la machine-outil

- Usinage et tests